As TUBU China, which has been deeply involved in the LED grow lighting field for more than 10 years, we understand the confusion that wholesale purchasers face when choosing LED grow lights. In this article, we will provide you with a comprehensive analysis of the core differences between quantum boards and traditional grow lights to help you avoid purchasing pitfalls and make wise business decisions.

The Technical Principle of Comparison: Why Quantum Plate Represents the Future?

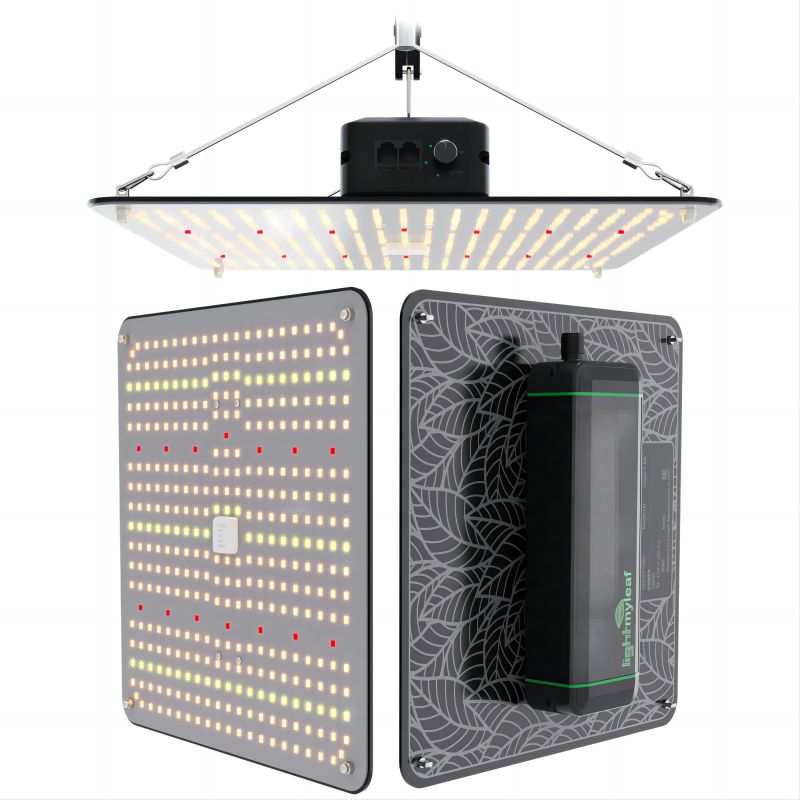

Quantum Board Grow Light Adopts the Latest Generation of LED Technology:

Using high luminous efficiency SMD or COB chips (we use imported Samsung/Lumileds chips)

Spectrum optimized for plant photosynthesis (380-780nm full spectrum coverage)

Equipped with a high efficiency heat dissipation system (aluminum substrate + aviation grade radiator)

Uniformity of light intensity of more than 90% (patented optical lens design)

Typical Features of Traditional Grow Lights:

Mostly High Pressure Sodium (HPS) or early LED technology

Poor spectral continuity, lack of key blue and violet light segments

High heat generation (HPS lamp surface temperature can reach more than 200 ℃)

Rapid light degradation (ordinary LEDs about 10,000 hours of light degradation of 30%)

TUBU measured data: under the same power, the PPFD value of the quantum plate is 40-60% higher than that of traditional lamps, and the energy consumption is reduced by 35%. 35% lower energy consumption

The Procurement Must Pay Attention to the 5 Core Parameters

PPF/PPFD Value (Photosynthetic Photon Flux Density)

Qualifying standards: 100-200μmol/m²/s in seedling stage, and 600+ in flowering stage

Be alert to false labeling: require suppliers to provide third-party test reports

Spectrogram Analysis

High-quality quantum board should present a bimodal curve (450nm blue light + 660nm red light)

Common spectral gaps in traditional lamps (lack of 500-600nm green and yellow light)

Energy Efficiency Ratio

Industry benchmark: more than 2.7μmol/J

TUBU quantum board up to 3.1μmol/J (40% higher than traditional lamps)

Heat Dissipation Performance

Key indicators: chip junction temperature <85℃

We use heat pipe + graphene composite heat dissipation technology

Warranty Period

High-quality suppliers should provide ≥ 3 years warranty

TUBU provides a 3-year warranty

The Wholesale Procurement of the 6 Pits to Avoid the Guide

Price Trap Identification

alert "low price, high quality": the same specification quantum board cost difference <15%

case: a brand 300W quantum board offer $ 80, the actual use of poor quality drive power supply

Sample Test Points

must be measured for more than 72 hours

Key observations: light decay curve, temperature changes, spectral stability

Certification Verification

Required certificates: CE, ROHS, UL8800

TUBU additional professional certifications such as DLC, EN62471, etc.

Supplier Evaluation Dimensions

Contract Considerations

Clearly agreed: light efficiency guarantee terms, attenuation rate standards

Suggested to add: batch sampling test failed return clause

After-sales Service Comparison

Choosing LED grow lights not only affects the purchasing cost, but also has a direct impact on the planting efficiency. TUBU China is willing to provide you with sample testing, planting program design, cost-benefit analysis with more than ten years of professional technical accumulation. Contact us now for wholesale.